Excitement About Aluminum Castings Company

Unknown Facts About Aluminum Castings Company

Table of Contents8 Simple Techniques For Aluminum Castings CompanyThe Ultimate Guide To Aluminum Castings CompanyAluminum Castings Company Things To Know Before You BuyThe Main Principles Of Aluminum Castings Company The Buzz on Aluminum Castings CompanyGetting The Aluminum Castings Company To WorkAluminum Castings Company for BeginnersIndicators on Aluminum Castings Company You Should KnowAluminum Castings Company Things To Know Before You Get This

Again, you're going to want to locate a casting shop that has actually done this previously. It's a whole lot simpler to sand ABS than light weight aluminum.

Have a look over here Comprehensive, patient-specific structural model solution from 3D Solutions precision healthcare remedies They point out Castform or thermojet Wax Patterns 3D Solution has the biggest portfolio of 3D Printers. We offer 3D Printing remedies for production, prototyping, spreading, oral and more. If you remain in the US you may wish to contact these men: They are a model vendror based in Seattle and provide a service called Quickcast.

Our Aluminum Castings Company Statements

gone to moeller a pair weeks back on a tour. I've never collaborated with them however, yet heard some scary things. heres the steez on their quickcastits a lighter RP component that has a honeycomblike interior permits the exhaustion to appropriately take place and is cheaper than normal SLA part. This process is normally utilized for HIGH tolerance parts to be cast in Titanium for like aircraft stuff.

i have actually done some sand spreading of aluminum and it's possibly a great way to go, like everyone else has actually said, relying on the time you agree to put into the component after the spreading is total - Sand Molding. you can, nevertheless make use of an RP component as a pattern for sand casting Fantastic info! I might still get in touch with Moeller - I want to ultimately try a small run of vessels and the much less job I have to to postcast, the far better

All About Aluminum Castings Company

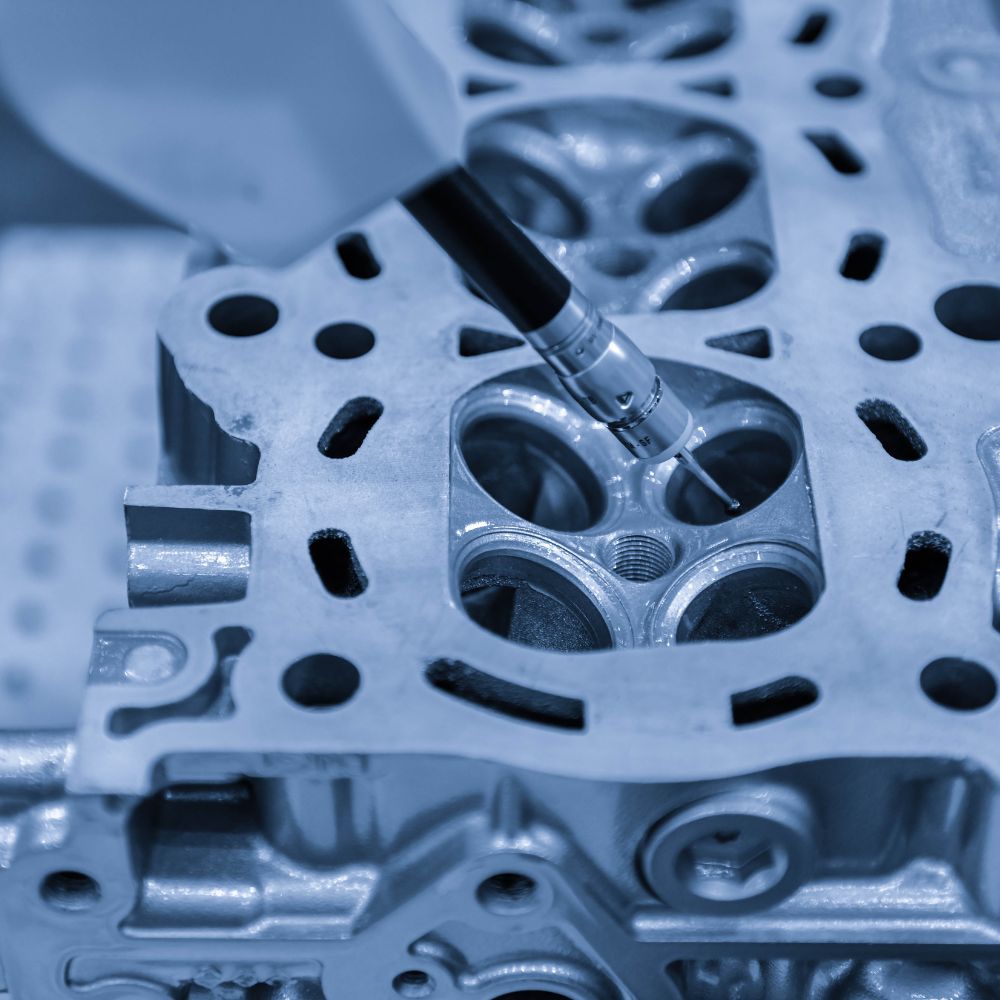

Machined to tolerances with a secondary procedure like thread cutting and dealing with. Steel spreading like shot molding utilizes a sprue and gateway system for mold flow however can fit a much greater variation in wall density. Ceramic covering investment procedure calls for no draft angles as the part is broken out of the ceramic as a one-off waste mold.

If strings always have to be machined after casting this is going to be a bit above budget. I listen to some factories can work with close resistances up to about +/ -0.010 in/in.

Many aluminum founders will place on a large song and dance number regarding helping you choose from the thousands of alloys that are offered. They will certainly after that clinically get to the best alloy and temper choice for your certain application. It constantly turns out to be 356-T6.;--RRB-;-- Lost foam is specifically excellent at challenging parts, where it would certainly be impossible to remove the pattern from the mold and mildew.

Unknown Facts About Aluminum Castings Company

Do not even try to begin with flimsy rolled sections; they'll move far from the cutter and 'sing' also at reduced feed rates - https://alumnmcstngs.start.page. If you've got the pin rate and feedrates high sufficient, milling is practically silent, the chips hit the ceiling, and they leave a mark . Mike HalloranNOT speaking for DeAngelo Marine Exhaust Inc

Hey there Elsmar forums, I work for a "Little" business in the Southeastern United State, our HQ is based in Italy. We just have both places and the firm specializes in Light weight aluminum Die Casting. The business that made use of to have the US operation is no more, and was purchased by the Italian business a little over a year ago.

The Basic Principles Of Aluminum Castings Company

Since this is such a small company, and has yet to tidy up the mess from the previous owner, I are accountable for 45 workers and 38 devices on my two shifts (2nd and Third Shifts). Being in charge of a lot was not something I had expected, yet I have actually made it my enthusiasm to develop a smooth procedure for my business.

We have actually lots of inherited issues, the most significant of which is our Lot Traceability - https://share.evernote.com/note/2aebfc36-8de1-e319-3c9a-69309bbb4272. and this is where I need every one of the help and recommendations I can get. The system embeded in area is utilized to trace the quality of 35 different products for various vehicle companies. Regarding half of our products are casted internal and machined in my side of the plant

Excitement About Aluminum Castings Company

We have lots of issues in our casting division, and its regularly boosting. The aluminum blocks supply very couple of issues and are much easier to regulate, however we still have our issues from time to time. Our whole lot tracing techniques seem extremely primitive, a literal tag (published sheet of paper) that physically complies with the parts.

We have won 14 new agreements in the last 4 months, and brand-new manufacturing is beginning within a year. We require to be able to narrow it down to the shift at a minimum. Ideally the time, driver, equipment, component #, set #, quantity.

The very same system needs to be made use of for all stages of manufacturing: Casting, Trimming, Shot Blasting, Machining, et all. I am an absolute amateur with this side of business, and have always stayed concentrated on preserving CNC makers, composing programs and leading jobs. Any kind of and all aid would be greatly valued.

Not known Details About Aluminum Castings Company

It's certainly a subject I have actually taken into consideration in detail and have had the advantage of having pals that were visite site professional foundrymen and capacity to observe their practices (Sand Foundry). There absolutely is no reason that industry ideal technique can not be achieved by a hobbysist, but whether that is practical or not because setting may be another matter

You can make and check all the example promo codes you like, but that does not mean your castings will uniformly exhibit the very same high qualities. Often times, the layout features of a casting will imply that it will not freeze evenly or in a directionally constant manner (thick sections/intersections for instance), and those locations are the ones probably to show H2 porosity and related reduce problems and seasoned foundrymen go right to them when they section and assess the spreading.

The Only Guide to Aluminum Castings Company

Commercial factories will purge and bury the melt in a holding heater simply to stop H2 seepage when there is no circulation! I make use of a repellent electric heater because it has no air circulation.

Aluminum Castings Company Fundamentals Explained

I'm a lost foam caster and my mold media is dry sand. As far as lost foam being more vulnerable to defects and porosity, I 'd state that has actually not been my experienec, at the very least no even more or much less than traditional sand casting.